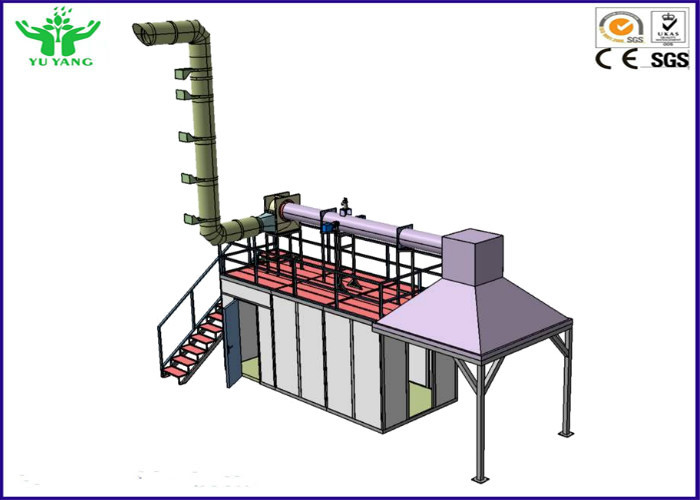

ISO 9705 Surface Products Full Scale Room Corner Test Heat Release Rate Fire Testing Equipment

Description:

Room Corner Test to perform fire reaction tests from Ineltec simulates a fire in a well-ventilated conditions started in a corner of a small room with one door open according to the standard ISO 9705:1993.

It is intended to evaluate the contribution to fire growth provided by a product surface using a specified ignition source.

The Room Corner Test ISO 9705 is particularly suitable for products that for some reason can not be tested in a small laboratory scale.

The method evaluates the fire characteristics of a surface product in a room fire scenario. The field of application is for building products that, for some reason, cannot be tested in small scale, for example thermoplastic materials, joint systems and materials with large irregularity. Other products can also be evaluated in the method, for example pipe insulation and upholstered furniture.

Standards:

ISO 9705: 1993 Fire Tests

The method measures the following: heat release rate (kW), total heat release (MJ) and smoke production rate (m2/s). The flashover phenomenon, flame spread and burning droplets or particles visually is also registered. When necessary, toxic gases can also be measured using FTIR analysis.

The method is also used for research purpose and for fire modelling studies.

ISO 13784-1 Reaction to fire test for sandwich panel building systems - Pars 1: Small room test

ASTM E1537 Test Method for Fire Testing of Upholstered Furniture

ASTM E603 Standards guide for room fire experiments

EN 14390: Fire Test- Full Scale Room Test for Surface Products

NFP A 265: Standard Methods of Fire Tests for Evaluating Room Fire Growth Contribution of Textile Covering on Full Height Panels and Walls

NFP A 286: Standard Methods of Fire Tests for Evaluating Contribution of Wall and Ceiling Interior Finish to Room Fire Growth

Test procedure:

During test, the test sample is mounted on the inside of the room, in the ceiling and on all the walls except for the wall with the door opening. A propane gas burner is located in one of the corners and produces a heat release rate of 100 kW during 10 minutes, and then 300 kW the following 10 minutes. The total test time is 20 minutes. The combustion gases are collected through a hood where heat release rate and smoke production are measured. Flame spread along walls and ceiling are observed visually. If flames emerge from the door opening, flashover has occurred and the test is terminated. The heat release rate at flashover is generally about 1 MW.

Main Features:

1, The test room is built by the density of 700kg / m³-A1 class fireproof material.

2, The internal dimensions of the room 3.6M X 2.4M X 2.4M

3, The gate size: 0.8M (W) X2.0M (H)

4, Sandbox burner with propane gas and equipped with emergency shut-off devices.

5, Automatic ignition system to automatically record experimental data;

6, Independently movable timet to display units.

7, 10kV spark ignition, a cease-fire with safety devices. Fire extinguishing drainage system design.

9, Equipped with staircase for easy maintenance exhaust pipes.

Gas sampling and analysis system

1, Gas sampling system includes an annular sampler probe, suction pump, particulate filter, a cold trap, exhaust valve, water filters and CO2 filter.

2, Three filters; Minimum filtration accuracy is 0.5um.

3, Freezing cold trap; air-conditioning compressor refrigeration systems; controlling the temperature in 0 ~ 5ºC.

4, Suction pump, Flow rate is 33L/min, vacuum is 700mmHg, and pressure is 2.5 bar.

5, Drying cylinder, which filter the water and impurities.

6, The flow controller to control the inspiratory air flow.

7, The sampler has 12 holes and gas flow in the opposite direction, these holds built-in dust filter and 685mm from hoods.

8, Paramagnetic oxygen analyzer, the range is 0-25%; linear response; imports Britain Servomex oxygen sensor.

Smoke system

1, 0.5W HE-NE laser source.

2, Thorlabs optically detector.

3, Motor driven 5 class automatically calibration device with of 0%, 25%, 50%, 75%, 100% transmittance filters.

4, One touch calibration system in software with digital and curve display.

DAQ System

1, 16bit data acquisition module.

2, Digital communication between computer and DAQ module.

3, Labview based application software on DAQ and data analysis.

Operating systems

1, Labview based application system, easily and precise to operate and control.

2, Test status, calibration status display on screen.

3, Device status are displayed on screen and indicators on panel.

4, Transducers data, process parameters, test result displayed on screen via digital and curve.

5, Test and calibration procedure auto executed by PLC program.

6, Device can be controlled via both application screen and control panel.

7, PC and PLC communicate with digital protocol which is safe and robust.

Technical parameters:

1, Paramagn etic oxygen analyzer, the concentration range is 0~25%, an oxygen analyzer is linear response, Britain Servomex oxygen sensor; 10% to 90% response time of less than 12s; output noise does not exceed 50ppm;. Reproduce the measured values lower than 100ppm,

2, Infrared CO2 analyzer range: 0 to 10%; accuracy of ± 0.01%;

3, The compressor works: cold trap: 0 to 5 degrees;

4, Import diaphragm pump, flow rate: 33 l / min

5, The standard detector color accuracy ± 5%, output linearity (transmission) <1%, absolute permeability <1%;

Test data:

1, Heat Release Rate (HRR),

2, Total Heat Release (THR),

3, Efficiency Heat Release (EHR),

4, Smoke Production Rate (SPR),

5, Time to Ignite (TTI),

6, Time to flameout,

7, Oxygen Consumption Rate,

8, CO2 Production Rate,

9, CO Production Rate,

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!