25m/min Needle Detector Machine with Conveyor Belt for Textile Fabric Garment

Description

The working principle of needle detector is that the upper and lower probes receive and process signals first, and then the strong electric integrated block, sensitivity control integrated block, signal receiving integrated block and signal output integrated block to complete the detection work.

When the goods through the needle testing machine have broken needle or contain iron metal and other substances, needle testing machine is not allowed to pass, detect iron metal needle testing machine will automatically alarm, and the conveyor belt back to the original position of goods; From and let inspectors according to the position of the broken needle signal indicator, can quickly find the broken needle goods, on the contrary, if there is no detection of metal goods can be through the needle machine channel. In accordance with the provisions of the export textile must go through the broken needle detection, through the needle detection machine broken needle qualified goods can be exported.

Products that pass can be packaged for export, otherwise they will be blocked at the customs

Characteristics

1. The newly developed high integrated chip of needle detector ensures high performance and reliability;

2. Needle detector has high sensitivity and anti-interference ability;

3. The needle detector adopts DIGITAL signal processing (DSP) from data acquisition to motor control, which is highly intelligent;

4. Needle testing machine is simple and easy to use, automatic data processing and saving, can keep the setting of shutdown every time boot;

5. High frequency switching power supply developed by needle testing machine, strong adaptability;

6. Needle testing machine adopts integrated design, optimize product design, reduce the number of components, by computer to replace the complex electronic components, so that the failure rate is doubled down;

7. Needle testing machine is controlled by computer precisely to prolong the life of the motor;

8. Needle inspection machine accurate counting, qualified, defective, total;

9. Needle testing machine will stop automatically after ten years of unmanned operation;

10. Needle testing machine can set the product testing time;

11. Needle detector with manual and automatic control two options, the operation is more convenient and flexible.

| Weight |

Appr160Kg |

| Alarm method |

Buzzer Lamp |

| Rated output |

Appr140W |

| Sensitivity |

1.2mm |

| Single package size |

165X105X90 cm |

| Belt operation mode once needle detected |

Rewind, rewind and falling down, stop (Optional) |

| Belt speed |

25m/min |

| Detection method |

Magnetic induction |

Needle testing machine constitution

1. Detection sensor (probe): it is composed of the upper detection sensor and the lower detection sensor (located below the conveyor belt), forming the height through which the detection items of different specifications can pass, referred to as detection height;

Principle: magnetic sensitive signal, referred to as magnetic cutting line

2. Circuit control system: signal amplification circuit and signal loop alarm system, power protection circuit consists of three parts

Principle: Iron foreign matter can be captured more quickly through signal amplification. When iron foreign matter hits and destroys the normal magnetic cutting line, the magnetic cutting line is distorted and deformed. At this time, the circuit outputs trigger signals to form an alarm loop to achieve the ideal effect of detection and alarm;

3. Electric machine: gear reduction single-phase capacitor rotation motor

Principle: Gear speed ratio rotation, reduce load, prolong life;

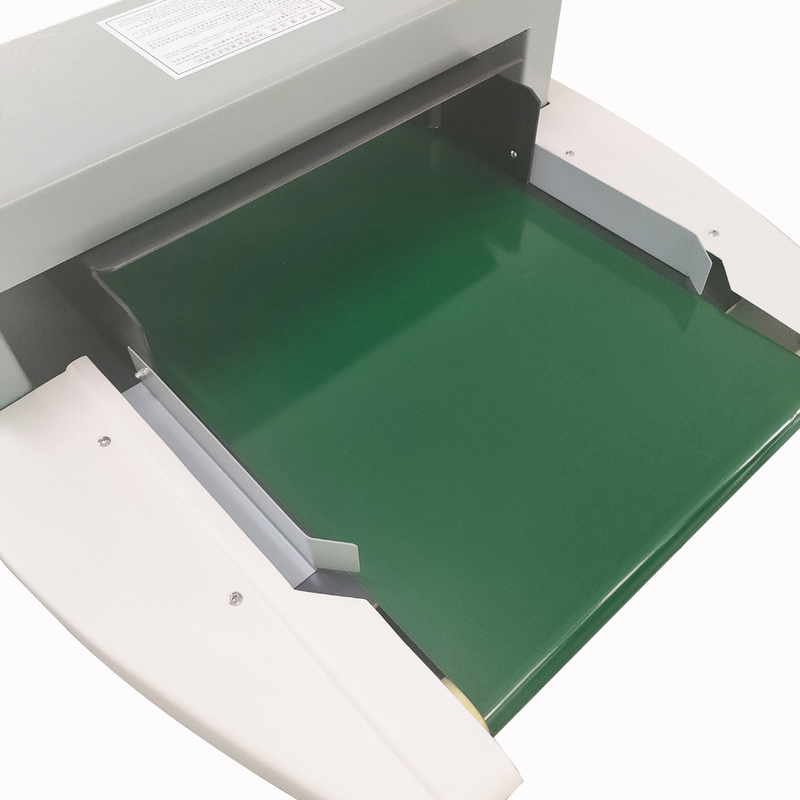

4. The conveyor belt, conveyor belt is used will need to test items carried detection sensor for testing tool, the steps of the so adopted anti-static special nylon, knitting woven mesh cloth, the surface adhesion of special rubber, absolute guarantee that the conveyor belt does not contain a little iron and metal components, to ensure the detection sensor without alarm;

5. Machine frame: the frame made of steel plate, to achieve the role of the bridge of the whole machine, is the primary frame of the multifunctional state structure of the needle machine, so that its performance is more stable, the appearance of electrostatic spraying, both beautiful and can prolong the service life;

6. Wing shell: both play the appearance decoration, the early use of aluminum plate production, relative to iron plate plays a certain signal shielding role, because the aluminum plate shell handmade, suitable for small production of manufacturers or customized non-standard machine, the strength of the manufacturers are using their own die-opening engineering hard plastic shell;

7. Drive shaft: stainless steel tube combined with flat bearing as the rolling structure of the four drive shafts, so that the concentricity of the drive to ensure smooth lubrication, low noise, low heat, prolong the service life;

8. Photoelectric infrared reflector - the working state will emit a beam of invisible infrared, when the detected objects through infrared interception and transmission signal to the recorder, and finally qualified items for counting;

9. Fixed feet: each machine has 4 fixed feet, which can be adjusted smoothly and firmly when installing the machine until the machine does not shake;

10. Control panel: used to control machine operation and sensitivity debugging, display counting and other functions.

DONGGUAN YUYANG INSTRUMENT CO.,LTD is Located in Wanjiang District (Dongguan City, Guangdong Province,China),a famous historical town with prosperous industry and convenient transportation.

We are a high-tech enterprise which is specialized in developing and manufacturing Fire Testing Equipment, Building Material Fire Tester, Wire and Cable Fire Tester, Environmental Test Chamber, Textile Testing Equipment, Toys Testing Equipment and etc.

Decades of research and development strengthen the leading edge of YUYANG in this field, and established as an crucial role in R&D on high quality and high-cost performance of testing equipment. YUYANG's testing equipment are widely used in various field: scientific institutions, colleges, inspection institutions, auto parts, electronics, electricals, lithium battery, LED, photoelectricity, mobile, plastic and rubber, display, telecommunication, chemical industry, aerospace, building material and product, wire and cable, toys, furniture, textile and fabrix, etc. All YUYANG testing equipment are designed according to international test standards, such as ISO, ASTM, DIN, EN, GB, BS, JIS, ANSI, UL, TAPPI, AATCC, IEC, VDE, CSA,CEN and so on.

DONGGUAN YUYANG INSTRUMENT CO.,LTD looks forward to cooperating with customer all over the world.

If you are interested in any of our products or would like to discuss a custom order. Please feel free to contact us. We are looking forward to forming succesful business with new clients around the world in the near future.

Certification

Customer Feedback

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!