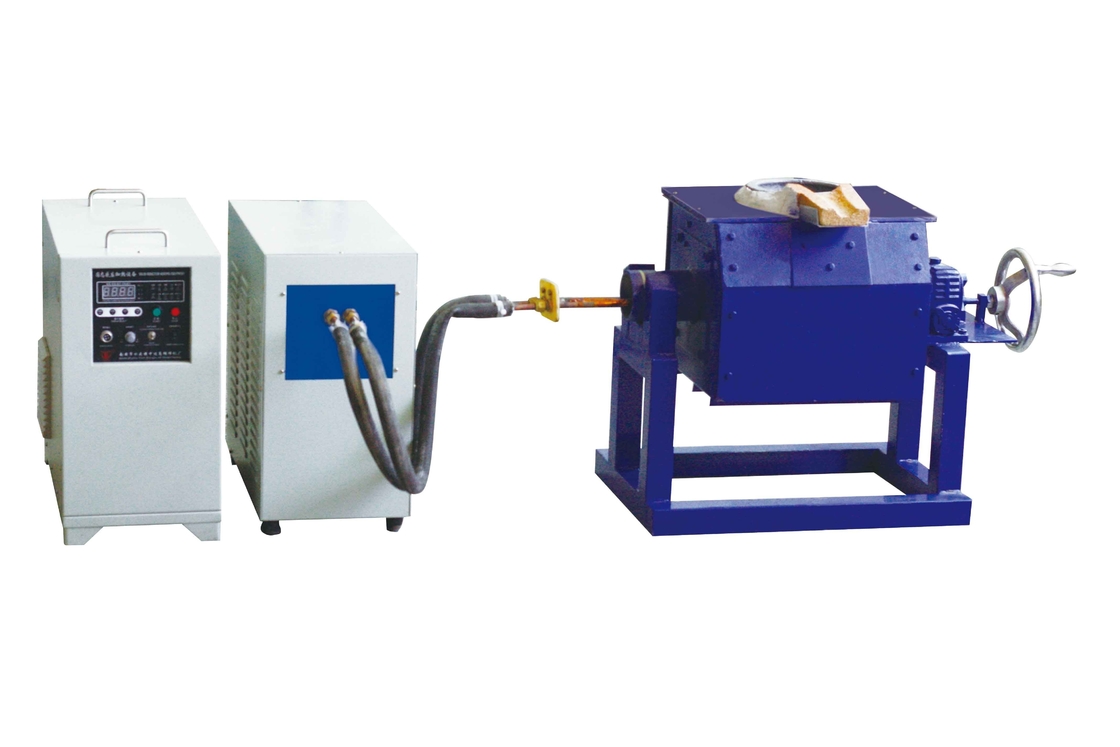

10kw High Frequency Induction Heating Machine for Testing Induction Heater

Product Description

Induction hardening of rails refers to a specific heat treatment technique that serves the purpose of enhancing the hardness

and wear resistance properties of linear guide rails. Thanks to the remarkable repeatability and controllability features of

induction hardening, the heat treatment procedure for the entire rail can be made more automated. Typically, we utilize a

specialized rail induction hardening machine to carry out the heating and cooling operations on the rails. Linear guide rails

play a crucial and indispensable role as components of machine tools. They are required to possess high levels of hardness

and wear resistance. Once the guide rails undergo the hardening process through induction hardening, their service life and

wear resistance capabilities will be significantly enhanced. In general, after the induction hardening of guide rails, an induction

tempering process is usually carried out subsequently. This induction tempering process can effectively and noticeably boost

the hardness of steel guide rails, decrease their brittleness, and improve their toughness performance.

Application:

A. Heating (hot forging, hot fitting and smelting):

1 Hot forging aims to fabricate the work pieces of certain temperature (different materials require different temperatures) into other shapes through forging press with the help of punch press, forging machine or other equipments, for instances, hot extrusion of watch case, watch flan, handle, mold accessory, kitchen and table ware, art ware, standard part, fastener, fabricated

mechanical part, bronze lock, rivet, steel pin and pin.

2. Hot fitting refers to the connection of different metals or metals with nonmetals through the heating based on the principle of hot expansion or hot smelting, for instances, embedded welding of copper core of computer radiator with aluminum sheet and speaker web, compound of steel and plastic tube, sealing of aluminum foil (tooth paste peel), motor rotor and sealing of tubular electric heating element.

3. Smelting mainly aims to melt the metal into liquid by using the high temperature, which is mainly applicable to the smelting of iron, steel, copper, aluminum, zinc as well as various noble metals.

B. Heat Treatment (surface quench):

It is mainly aims to change the rigidity of the metal materials through the heat treatment to work pieces. Detail applications are

stated as follows:

1. Quench for various hardware and tools, such as plier, wrench, hammer, ax, screwing tools and shear (orchard shear).

2.Quench for various automobile and motorcycle fittings, such as crankshaft, connecting rod, piston pin, chain wheel, aluminum

wheel, valve, rock arm shaft, semi drive shaft, small shaft and fork.

3. Various electric tools, such as gear and axes.

4. Quench for machine tools, such as lathe deck and guide rail.

5. Quench for various hardware metal parts and machined parts, such as shaft, gear (chain wheel), cam, chuck and clamp etc.

6. Quench for hardware molds, such as small-size mold, mold accessory and inner hole of mold.

C. Welding (braze welding, silver soldering and brazing)

It mainly aims to melt the solder by heating it to a certain temperature for the purpose of connecting two types of metals of the same material or different materials.

1. Welding of various hardware cutting tools, such as diamond tool, abrasive tool, drilling tool, alloy saw blade, hard alloy

cutter, milling cutter, reamer, planning tool and solid center bit.

2. Welding of various hardware mechanical gadget: Silver soldering and brazing of metals of the same variety or different

varieties, such as hardware toilet and kitchen products, refrigerating copper fitting, lamp decoration fitting, precision mold fitting, hardware handle, eggbeater, alloy steel and steel, steel and copper as well as copper and copper.

3. Compound pot bottom welding is mainly applicable to the braze welding of circular, square as well as other irregular plain pot bottom. It is also applicable to plain braze welding of other metals.

4. Welding of heating disc of electric hot-water kettle mainly refers to the braze welding of stainless steel flat base,

aluminum sheet and tubular electric heating elements of various forms.

D.Annealing (tempering and modulation):

1. Annealing of various stainless steel products, such as stainless steel basin, annealed and extruded can, annealed folded edge, annealed sink, stainless steel tube, tableware and cup.

2. Annealing of various other metal work pieces, such as golf ball head, cue, brass lock, hardware copper fitting, kitchen knife handle, blade, aluminum pan, aluminum pail, aluminum radiator and various aluminum products.

Packaging & Transportation

About us

FAQ

1. who are we?

We are based in Guangdong, China, start from 2018,sell to Southeast Asia(11.00%),Eastern Asia(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),Northern Europe(9.00%),South Asia(9.00%),North America(7.00%),South America(7.00%),Western Europe(7.00%),Eastern Europe(6.00%),Mid East(6.00%),Oceania(5.00%),Central America(3.00%),Africa(0.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Environmental Test Chamber,Fire Testing Equipment,Tensile Testing Machine,Induction Heating Machine

4. why should you buy from us not from other suppliers?

We are a high-tech enterprise which is specialized in developing and manufacturing Fire Testing Equipment, Building Material Fire Tester, Wire and Cable Fire Tester, Environmental Test Chamber, Textile Testing Equipment, Toys Testing Equipment and etc.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P ,Credit Card,PayPal,Western Union,Cash,Escrow,D/A,;

Language Spoken:English,Chinese

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!