16 CFR1633 Mattresses Open Flame Testing Machine, Fire Testing Equipment

Purpose:

This part 1633 establishes flammability requirements that all mattress sets must meet before sale or introduction into commerce. The purpose of the machine is to reduce deaths and injuries associated with mattress fires by limiting the size of the fire generated by a mattress set during a thirty-minute test.

The machine is used to evaluate the fire progression and energy output in a mattress or a mattress set when subjected to an ignition source approximate to burning bed clothes.

16 CFR Part 1633 is a federal standard in USA and all manufactured or imported mattresses and mattress sets must meet this standard.

Standard:

16 CFR Part 1633 "Standard for the Flammability (open flame) of Mattresses sets".

Features:

The mattress or mattress set is located on top of a steel rig and exposed to two T-shaped burners with a total burner heat output of 27 kW. The side burner is applied for 50 seconds and the top burner is applied for 70 seconds. The fire is then allowed to develop freely. The smoke gases produced during the test are collected by a hood and exhaust system from where samples are taken for gas analysis. Heat release rate is measured continuously. The peak rate of heat release of may not exceed 200 kW and the total heat release in the first 10 minutes of the test of may not exceed 15 MJ.

Test method:

The test method set forth in § 1633.7 measures the flammability (fire test response characteristics) of a mattress specimen by exposing the specimen to a specified flaming ignition source and allowing it to burn freely under well-ventilated, controlled environmental conditions. The flaming ignition source shall be a pair of propane burners. These burners impose differing fluxes for differing times on the top and sides of the specimen. During and after this exposure, measurements shall be made of the time-dependent heat release rate from the specimen, quantifying the energy generated by the fire. The rate of heat release must be measured by means of oxygen consumption calorimetry

Technical requirements:

The peak rate of heat release shall not exceed 200 kilowatts (‘‘kW’’) at any time within the 30 minute test;

The total heat release shall not exceed 15 megajoules (‘‘MJ’’) for the first 10 minutes of the test.

Main parameters:

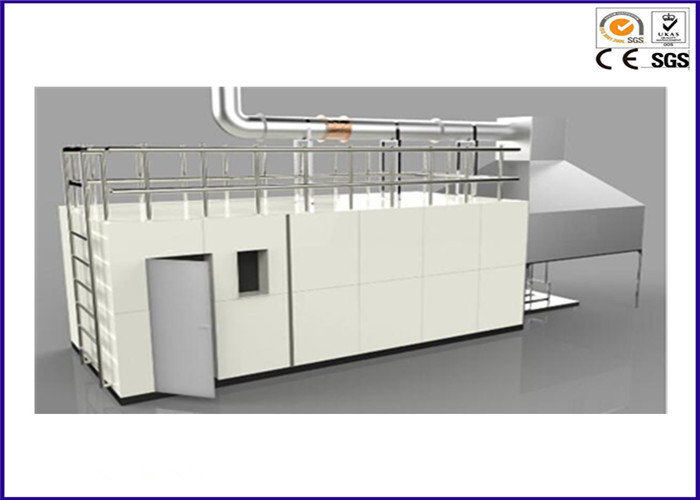

The test machine includes test room, control chamber, exhaust duct, exhaust fume-collecting hood, data acquisition system, and etc.

1. Combustion chamber (test room, customer build it by themselves) and gas-collecting hood: size 3048 * 3658 * 2438 mm (length x width x height).

2. Domestic oxygen analyzer:

Output: 4-20mA, two ways relay alarm

Measurement range: 0 ~ 25% VOL, accuracy: 0.5FS;

Power supply: 220VAC

Response time: 3 second

Accuracy: ±1% F•S

3. T-shaped burners:

1) Top surface burner, The T head of the top surface burner (horizontal

burner) shall be

305 ±2mm long with gas tight plugs in each end. Each side of the T shall contain 17 holes equally spaced over a 135 mm length (8.5 mm ± 0.1 mm apart). The holes on each side shall begin 8.5 mm from the centerline of the burner head. The holes shall be drilled with a #56 drill and are to be 1.17 mm to 1.22 mm in diameter. The holes shall be pointed 5 ° out of the plane of the Figure. This broadens the width of the heat flux profile imposed on the surface of the test specimen.

2) Side surface burner, The T head of the side surface burner (vertical burner) shall be constructed similarly to the top surface burner, except that its overall length shall be 254 ± 2 mm . Each side of the burner head shall contain 14 holes spaced evenly over a 110 mm length (8.5 mm ± 0.1 mm apart). The holes shall be drilled with a #56 drill and are to be 1.17 mm to 1.22 mm in diameter. The holes shall be pointed 5 ° out of the plane of the Figure.

4. Burner stand-off, consist of a collar fixed by a set screw onto the inlet tube of the burner head, shall hold a 3 mm diameter stainless steel rod having a12.7mm by 51mm by (2 –2.5mm) thick (0.5 in by 2 in by (0.08 –0.10) in thick) stainless steel pad welded on its end with its face (and long axis) parallel to the T head of the burner.

5. Gas supply system:

Combustion gas: propane

46.5 ± 0.5 MJ/kg

Gas flow accuracy: ≤ 0.1l/min (when flow is 12.9l/min)

≤ 0.05L/min (when flow is 6.6 L/min).

The rate: top burner 12.9 ± 0.1 L/min, side burner 6.6 ± 0.05 L/ min

6. Record data acquisition system can collect oxygen concentration, carbon monoxide concentration, temperature, smoke density, heat release rate, mass loss rate, etc., can be stored.

7. Fan: 2.2KW

8. Power supply: AC 380V 50HZ

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!