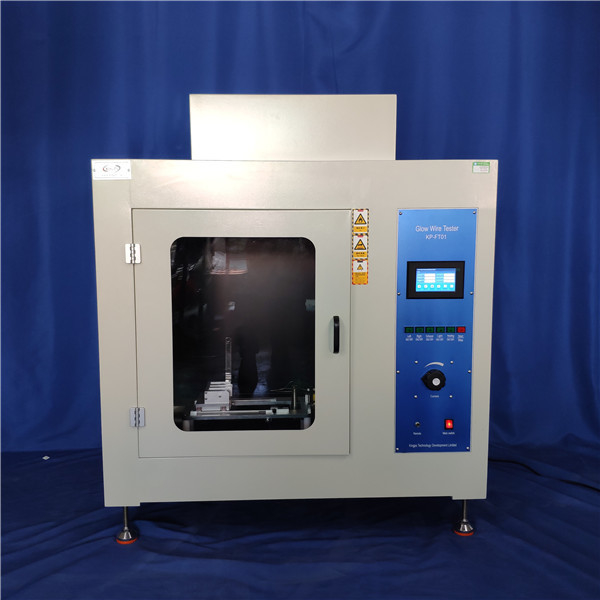

Glow Wire Testing Instrument/IEC 60695-2-10 Glow Wire Test Apparatus Glow Wire Tester

Introduction

Glow wire tester is a simulation experiment project using non-flame ignition source in accordance to standard requirements of IEC60695-2-10,UL 746A ,GB/T5169.10,GB4706.1.It makes required material(Ni80/Cr20) and heating wire in required shape(Φ4mm-chromel-filament)heated up to test temperature( 550 ℃ ~ 960 ℃) for 1min and then broil the specimen using required pressure (0.95N) for 30s at vertical direction;to check whether the specimen and bedding material ignite and lasting ignition time to test the ignition fatalness of electrical and electronic finished devices

Test the ignition performance,ignition temperature (GWIT),solid insulating material and other solid combustible material,combustibility and flammability index(GWFI).

It can be applied to research,production and quality testing department of electrical and electronic devices and component parts like lighting equipment,low voltage apparatus,eletrotechnical instrument,etc.

Feature

1. Glow wire tester is in accordance with IEC60695-2-10, UL 746A, GB/T5169.10, GB4706.1

2.Thermocouple: model K Type imported insulating thermal stabilized sheathed thermocouple, heat resistance 1100°c

3.Glow wire temperature: 500°c-960°c (presentable data display),temperature fluctuation<3°c

4.Test pressure of specimen: 1.0N±0.1N

5.Max thermal depth: 7mm±0.5mm(adjustable)

6.Movement velocity of specimen: 10mm/s-25mm/s

7.Test time: 30s+0.1s(1-999.9s data display presentable)

Technical Parameter

1. Glow wire temp: 100~1000℃±2℃ (Constantly adjustable)

2. Broil time: 0-999.9s±0.1s adjustable (Generally choose 30s)

3. Ignition time: 0-999.9s±0.1s, automatic record, suspension by wire

4. Smother time: 0-999.9s±0.1s, automatic record, suspension by wire

5. Thermocouple: Φ1.0mm imported armour (K type)

6. Glow wire: Φ4 mm chromel-filament (Ni80/Cr20)

7. Broil into depth: 7mm±0.5mm

8. Specimen pressure: 0.95N±0.1N

9. Test speed: 10 mm/s to 25 mm/s.

10. Standard: IEC60695-2-10.

11. Test procedure: Automatic control, Independent exhaust system

12. Reference standard: IEC60695-2-10:2000,UL746A

13. Studio volume: Bigger than 0.5 cubic meter (can be customized as 0.75 or 1cubic meter)

14. External dimension: 1100mmW×700mmD×1300mm

15. Control: Single chip Microcomputer touch screen+button type double control system, high accuracy temperature gauge,independent electrical control system, strong anti-interference.

16. Operation with high efficiency: One-touch operation, fast and highly effectively

17. Standard integration: Program test procedures in accordance with actual test procedures.

|

Glow wire

|

diameter 4mm±0.07mmNi/Cr(80/20), standard

|

|

Temp Range

|

100-1000°C ±2°C continus adjustable

|

|

Thermocouple

|

diameter 1.0mm Type K (Ni/Cr~Ni/Al),armored sheath can withstand temperature -40~ 1100°C

|

|

Searing Time

|

30s±0.1s (OMRON H5CN-XAN-Z digital timer, 0-9999s, presettable)

|

|

Light-off Time

|

0-999.9 s ± 0.1 s, automatic recording, manual timeout

|

|

Fireout Time

|

0-999.9 s ± 0.1 s, automatic recording, manual timeout

|

|

Ironing into depth

|

7mm ± 0.5 mm

|

|

Sample pressure

|

0.95N ± 0.1 N

|

|

Test speed

|

10 mm/s to 25 mm/s

|

|

Control

|

Using single chip microcomputer + touch screen control

|

|

Power Supply

|

220V, 48-60Hz

|

|

Consult standard

|

IEC60695-2-10:2013,UL746A

|

|

Chamber

|

≥0.5m

|

FAQ

1. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

2. What can you buy from us?

Fire Testing Equipment,Environmental Test Chamber,Textile Testing Equipment,Toys Testing Equipment,Wire and Cable Test Machine

3. Why should you buy from us not from other suppliers?

We are a high-tech enterprise which is specialized in developing and manufacturing Fire Testing Equipment, Building Material Fire

Tester, Wire and Cable Fire Tester, Environmental Test Chamber, Textile Testing Equipment, Toys Testing Equipment and etc.

DONGGUAN YUYANG INSTRUMENT CO.,LTD is Located in Wanjiang District (Dongguan City, Guangdong Province,China),a famous historical town with prosperous industry and convenient transportation.

We are a high-tech enterprise which is specialized in developing and manufacturing Fire Testing Equipment, Building Material Fire Tester, Wire and Cable Fire Tester, Environmental Test Chamber, Textile Testing Equipment, Toys Testing Equipment and etc.

Decades of research and development strengthen the leading edge of YUYANG in this field, and established as an crucial role in R&D on high quality and high-cost performance of testing equipment. YUYANG's testing equipment are widely used in various field: scientific institutions, colleges, inspection institutions, auto parts, electronics, electricals, lithium battery, LED, photoelectricity, mobile, plastic and rubber, display, telecommunication, chemical industry, aerospace, building material and product, wire and cable, toys, furniture, textile and fabrix, etc. All YUYANG testing equipment are designed according to international test standards, such as ISO, ASTM, DIN, EN, GB, BS, JIS, ANSI, UL, TAPPI, AATCC, IEC, VDE, CSA,CEN and so on.

DONGGUAN YUYANG INSTRUMENT CO.,LTD looks forward to cooperating with customer all over the world.

If you are interested in any of our products or would like to discuss a custom order. Please feel free to contact us. We are looking forward to forming succesful business with new clients around the world in the near future.

Certification

Customer Feedback

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!