UV Aging Test Lamp for Bituminous Materials with 220v Voltage Current Power Monitor Power Factor Frequency Energy Meter

Description:

UV Accelerated Test Chamber is applicable for the sunlight resistant test of nonmetallic materials and aging test of artificial light sources. A variety of industrial products can make the reliability test, and this product can simulate the product in the sun, rain, humidity and dew conditions, including damage caused by bleaching, color, brightness down, powder, crack, blur, brittle, intensity decreased and oxidation.

Technical parameters:

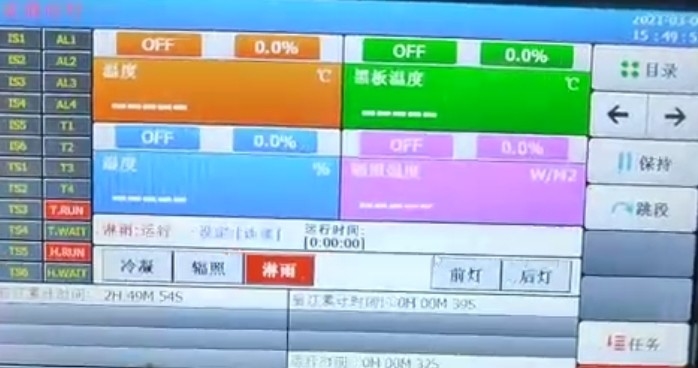

Studio Size 400W×1140D×390Hmm

Outside dimension 500W×1300D×1360Hmm

Materials Inside and Outside SUS#304 stainless steel

Temperature range RT+10~100°C

Temperature uniformity ±2°C

Temperature fluctuation ±0.5°C

Temperature control PID SSR control

Humidity range: ≥90%RH

Controller Korean TEMI 880 programmable controller

Control mode Balance temperature humidity control (BTHC)

Test cycle setting Illumination, condensation and water spray test cycle is programmable

Lamp power 40W/Piece

Distance from sample to lamp 50±2mm (adjustable)

Centre distance between the lamp 70mm

Irradiance 0.1 W/m² to 1.0 W/m²

Wavelength ultraviolet light UV-B: 280-315nm (8pcs, 2000h lifetime)

Effective irradiation areas 640×1140mm

Irradiation black panel temperature 50°C~70°C

Standard Specimen Size 75×150mm and 100×300mm

Required water depth for water channel 25mm, automatically control

Testing time 0~999H, adjustable

Power 220V/50Hz /±10% 3KW

Protection system Overload short circuit protection, over temperature protection, water lackin

Rain Time: 0 to 1000 min

Rain Interval: 0 to 1000 min

Water: distilled water

Water Consumption: 8 Liters/day

3. Chamber Structure:

The inner bladder of the chamber is made of imported high-class stainless steel plate while the outer bladder is made of SUS 304 steel plate.

The heating mode adopts inner bladder trough type heating with its rapid temperature rise and even temperature distribution.

4. Control System:

Adopts black aluminum plate to connect temperature sensor and adopts black board temperature meter to control heating so as to ensure more stable temperature.

The radiometer probe is fixed so as to avoid the frequent installation and disassembly.

The radiation quantity adopts the special UV irradiatometer with high-precision display and measurement.

The radiation intensity is not more than 50W/m2.

The illumination and condensation can be controlled independently or alternating and circularly.

5. Test Specimen Mounting:

The standard test specimen holder accommodates 48 pcs 75×150mm, the test panels are actual the side wall of the chamber. To properly seal the chamber, it is important to have every panel holder filled with specimens or blank panels and to have panel holders in place.

6. Design criteria:

(1) ASTM D4587: Standard Practice for Fluorescent UV-Condensation Exposures of Paint and Related Coatings

(2) ASTM D4799: Standard Practice for Accelerated Weathering Test Conditions and Procedures for Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)

(3) ISO 4892-1: Plastics - Methods of Exposure to Laboratory Light Sources - Part 1: General guidance

(4) ISO 4892-3: Plastics - Methods of Exposure to Laboratory Light Sources - Part 3: Fluorescent UV Lamps

(5) ASTM D4329: Standard Practice for Fluorescent UV Exposure of Plastics

(6) AATCC TM186: Weather Resistance: UV Light and Moisture Exposure

(7) ASTM D5208: Standard Practice for Fluorescent Ultraviolet (UV) Exposure of Photodegradable Plastics

(8) IEC 61345: UV Test for Photovaltalic (PV) Modules

Our Company:

GAUNGDONG YUYANG INSTRUMENT CO., LTD is located in Minhang District (DONGGUAN City, China), a dynamic area with a prosperous economy and well - connected transportation. We are a high - tech firm specialized in developing and manufacturing Flammability Testing Equipment for Textiles, Building Material Smoke Density Testers, Wire Insulation Testers, Environmental Humidity and Temperature Test Chambers, Textile Pilling Testers, Toy Flammability Testing Instruments, and so on. Decades of research and development have strengthened YUEJIN's leading position in the industry. We are an important contributor to the R & D of high - quality and high - cost - performance testing equipment. Our products are widely used in scientific institutions, universities, inspection agencies, the automotive industry, electronics manufacturing, electrical engineering, lithium - battery production, LED and photoelectric industries, mobile device manufacturing, plastic and rubber sectors, display manufacturing, telecommunication fields, chemical industries, aerospace, building material production, wire and cable manufacturing, toy production, furniture making, textile and fabric industries, etc.

If you are interested in any of our products or would like to discuss a custom order. Please feel free to contact us. We are looking forward to forming succesful business with new clients around the world in the near future.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!