1. Glow wire tester Accord with IEC 60695-2-11, UL 746A, GB/T 5169.10, GB 4706.1

2. Glow wire tester Using electricity heating regulation material (Ni80 / Cr20) of resistance wire (Φ 4 mm Ni-Cr alloy wire) to 0°C~ 1000°C in 1 min, then with 1.0 N vertically burn it 30s,measure the fire risk by product light-off or hold burning time, also test light-off degree, light-off temperature (GWIT), flammability and combustible index (GWFI).

3. Lab glow wire tester Suitable for lighting equipment, low voltage electric appliance, electrician instruments and material flammability testing, such as electrical and electronic products.

1. Glow wire tester is in accordance with IEC 60695-2-11, UL 746A, GB/T 5169.10, GB 4706.1

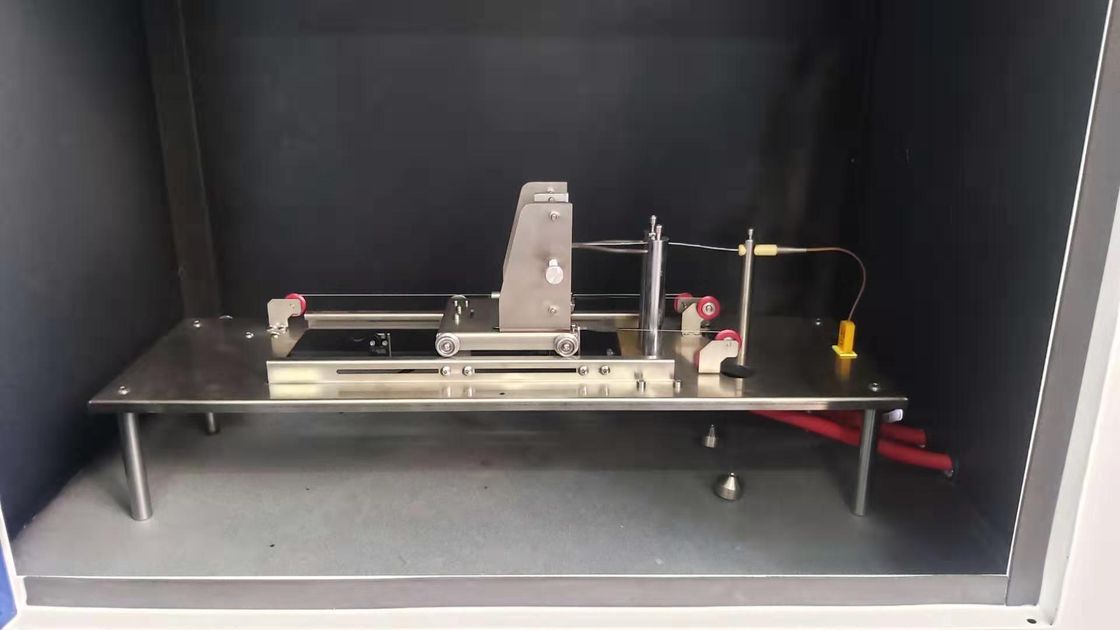

2.Thermocouple: model K Type imported insulating thermal stabilized sheathed thermocouple, heat resistance 1100°c

3.Glow wire temperature: 500°c-960°c (presentable data display), temperature fluctuation<3°c

4.Test pressure of specimen: 1.0N±0.1N

5.Max thermal depth: 7mm±0.5mm(adjustable)

6.Movement velocity of specimen: 10mm/s-25mm/s

7.Test time: 30s+0.1s(1-999.9s data display presentable)

Advantages:

1. Can meet different test methods and standards, GB, ISO, ASTM test methods setting freely.

2. LCD display touch screen all the test result, data and curve.

3. Wrapping connector driving system to make working more stably and more precision.

4. Microcomputer controlling, all keyboard operation.

5. Automatic judgment materials slide adhesive state and sample test results between quantitative discrete analysis.

6. Static friction coefficient and dynamic friction coefficient option freely, flexible test.

7. Can save 6 test results and data and display the curve. Also with query function.

Standards:

IEC 60695-2-11, IEC 60695-11-2

Specification:

1. The glow-wire temperature: 550 ~ 1000C adjustable, when 500 ~ 750C ±2C, when 750 ~ 1000C ± 5C

2. Test time: 30s±0.1s

3. Layer: thickness 10mm wooden board 12g /m 2 ~ 30g /m 2 wrapping tissue, is positioned 200mm ± 5mm below test specimen.

5. Thermocouple: K type thermocouples Φ0.5mm

6. The glow-wire: Φ4 mm±0.04mm Ni/Cr(80/120) nickel chromium wire.

7. Hot depth: 7mm ± 0.5mm (1N ± 0.2N maintaining the pressure of hot into the sample)

8. Test speed: 10mm/s~25mm/s.

9. The testing process: test procedures automatic control, independent ventilation

10. The reference standard: GB/T 5169.10, IEC 60695-2, UL 746A

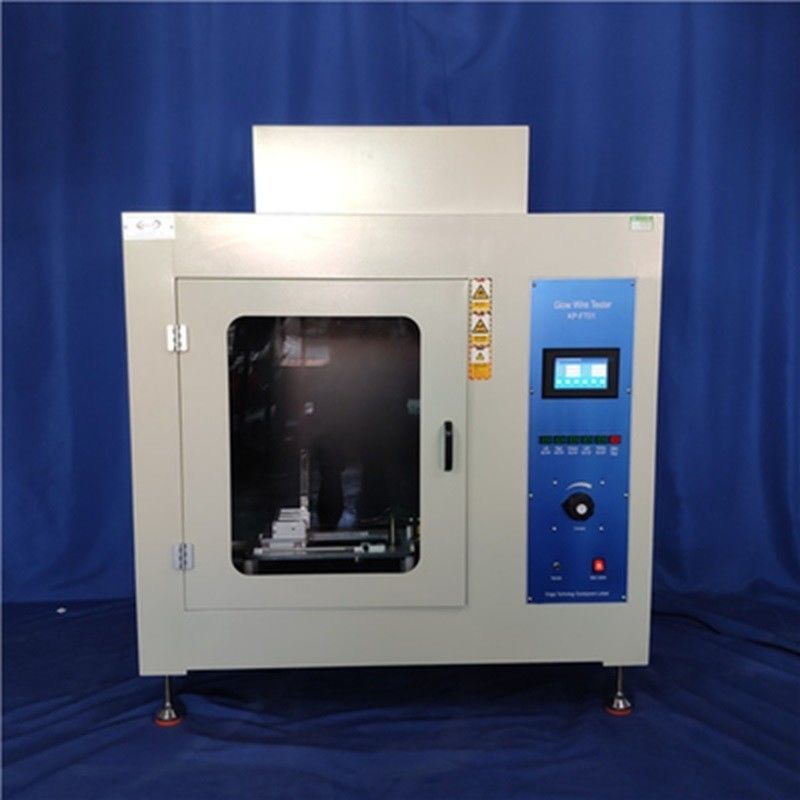

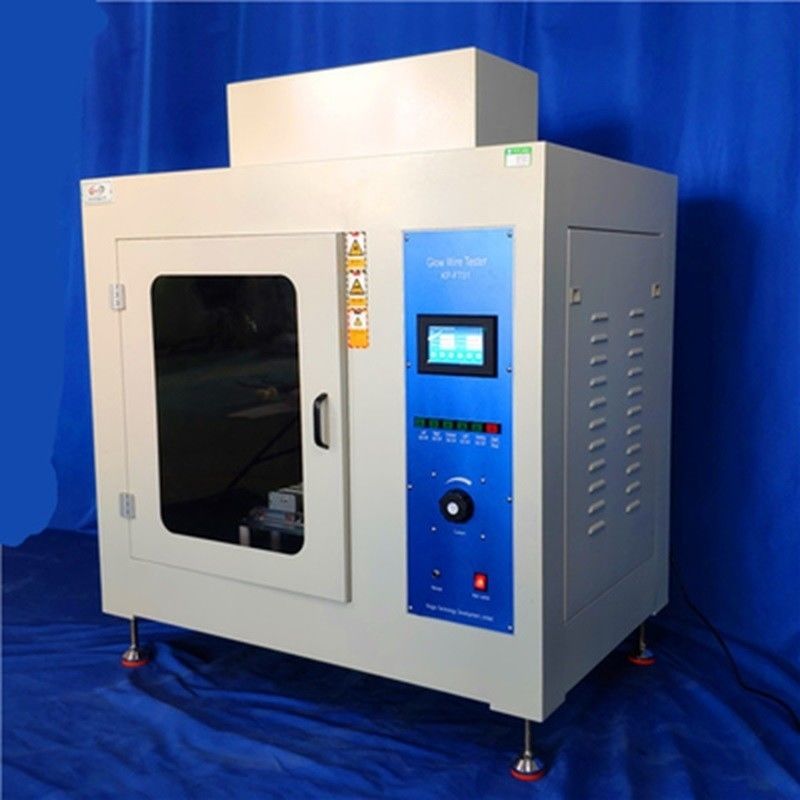

11. Studio Volume: ≥0.5 m3

12. The device outside dimensions: 1150mm wide × 650mm deep × 1300mm high, exhaust vent 100mm

13. Power supply: 1kVA 220V 50/60HZ

FAQ

1. who are we?

We are based in Guangdong, China, start from 2018,sell to Southeast Asia(11.00%),Eastern Asia(10.00%),Southern Europe(10.00%),Domestic Market(10.00%),Northern Europe(9.00%),South Asia(9.00%),North America(7.00%),South America(7.00%),Western Europe(7.00%),Eastern Europe(6.00%),Mid East(6.00%),Oceania(5.00%),Central America(3.00%),Africa(0.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Environmental Test Chamber,Fire Testing Equipment,Tensile Testing Machine,Induction Heating Machine

4. why should you buy from us not from other suppliers?

We are a high-tech enterprise which is specialized in developing and manufacturing Fire Testing Equipment, Building Material Fire Tester, Wire and Cable Fire Tester, Environmental Test Chamber, Textile Testing Equipment, Toys Testing Equipment and etc.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P ,Credit Card,PayPal,Western Union,Cash,Escrow,D/A,;

Language Spoken:English,Chinese

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!