Flooring Radiant Panel Test Apparatus, 0~15KW/W2 Heat Flux Flammability Testing Equipment

Product introduction:

This test method is used to measure the critical radiant flux of horizontally-mounted floor covering systems exposed to a flaming ignition source in a graded radiant heat environment, within a test chamber. It can also be used to measure this same critical radiant flux for exposed attic floor cellulose insulation.

The European Union is using this test method for fire classificaiton of flooring products, throughout European Member States.

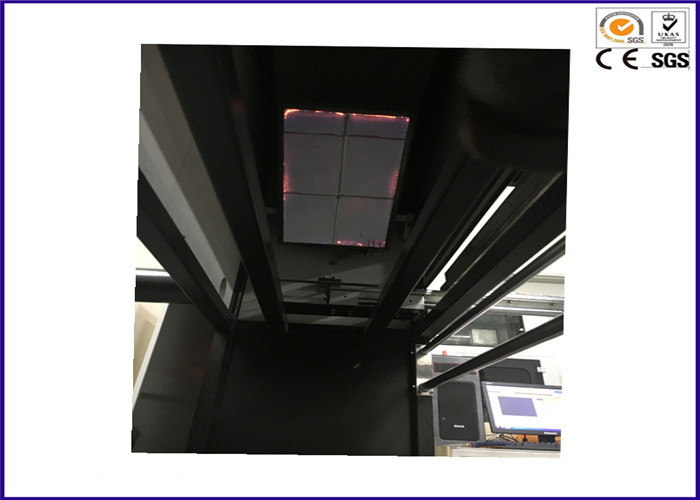

The radiant heat is applied by means of a gas-fuelled panel, inclined at 30º, and directed at a horizontally mounted floor covering system specimen. The radiant panel generates a radiant energy flux distribution ranging from a nominal maximum of 10.9 kW/m2 to a minimum of 1.1 kW/m2.

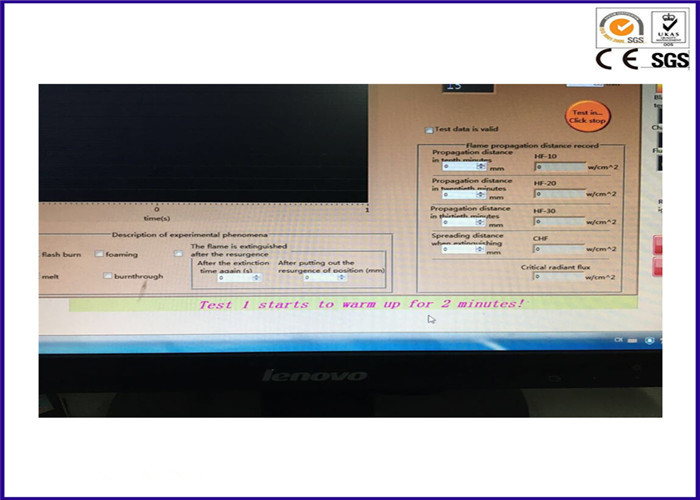

A small stainless steel pilot burner assists in specimen ignition.

The distance burned until flame-out is reached and converted, by calibration, into an equivalent critical radiant flux, in kW/m2.

A smoke measuring system, according to DIN 50055, is mounted on a separate frame at the exhaust stack.

Traditionally, tests are conducted to give a maximum critical radiant heat flux of 10.9 kW/m2, but it can optionally be conducted with higher radiant heat input, of up to 25.0 kW/m2.

Features:

1. Angled Control Rack for convenience in use, allowing observation of the apparatus and controls duing equipment set-up and calibration.

2. Automatic ignition of the radiant panel and safety cut-out.

3. Hinged access to test area, via 2 position door with observation window and sliding platform.

4. Stainless steel hood with smoke measurement ports.

5. Data acquisition and analysis software

BS EN ISO 9239_1-2010.pdf

ASTM E648-2015 (2).pdf

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!