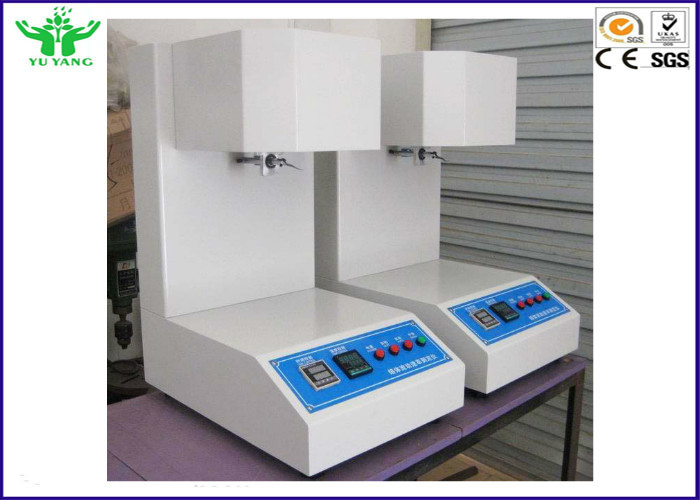

100~450℃ Melt Flow Index Tester MFR MVR Thermoplastics ISO 1133 ASTM D1238

ISO 1133 Vs. ASTM D1238

ISO and ASTM offer their standards for purchase at their respective websites.

In the world of plastics, melt flow index measures the output rate -- or flow -- that occurs in natural polymer or masterbatch over the course of 10 minutes when a piston applies a fixed amount of pressure at 190 degrees Celsius. Knowing the MFI helps manufacturers asses the viscosity of a substance to better control its processing. The International Organization for Standardization's 1133 and the American Society for Testing and Material's ASTM D1238 both serve as standards for measuring melt flow index.

Description:

The melt mass-flow rate (MFR) and the melt volume-flow rate (MVR) are determined by extruding molten material from the barrel of a plastometer under preset conditions of temperature and load. For melt mass-flow rate, timed segments of the extrudate are weighed and the extrudate rate is calculated in g/10 min and recorded. For melt volume-flow rate, the distance that the piston moves in a specified time or the time required for the piston to move a specified distance is measured to generate data in cm3/10 min. Melt volume-flow rate may be converted to melt mass-flow rate, or vice-versa, if the density of the material is known under the conditions of the test.

Standards:

ISO1133, ASTM D1238, ASTM D3364, BS2782, DIN53735, JIS K7210

Similarities

ISO 1133 and ASTM D1238 have more similarities than differences. Manufacturers consider these standards “technically equivalent,” as both detail similar standards for using an extrusion plastometer, which is commonly known as a melt indexer. Both standards present tests that measure one point on the viscosity curve under controlled conditions and both express MFI in units of grams per 10 minutes. Each standard specifies orifice length and diameter, barrel temperature and piston load ratings.

Methods

While the ISO 1133 standard requires a five-minute preheat time, ASTM D1238 requires a seven-minute preheat time. The ISO 1133 standard has a starting point of 50 mm and entails 30 mm of piston travel whereas the ASTM D1238 method has a starting point of 46 mm and entails between 6.35 and 25.4 mm of travel. Additionally, ISO and ASTM standards propose a slight dimensional difference in the piston foot of the melt indexer.

Features:

ASTM D1238 offers a variation of the melt-flow test known as a multi-weight melt flow test. This procedure -- which uses different weights of materials -- offers multiple measurements on a single charge, including measurements under varying load conditions. The ISO 1133 standard does not detail this alternative method. The ASTM standard also details recommended technical specifications for melt indexers, while ISO 1133 lacks this feature.

Procedures A and B

ISO 1133 and ASTM D1238 both offer two MFI test methods, known as Procedures A and B. Procedure A relies on a manual melt indexer making cuts at timed intervals that are then weighed on an analytical balance to determine MFI, while Procedure B features no cutting or weighing. Instead, it determines MFI via measuring a volume of extruded resin. Typically, Procedure B produces more accurate measurements as it has less opportunities for user interference. However, this procedure requires an accurate value for the resin melt density at the test temperature, while Procedure A does not require this knowledge.

Specifications:

| Model |

|

YY166 |

| Temperature range |

℃ |

100~450 |

| Temperature accuracy |

℃ |

±0.5 |

| Temperature variation in 4 hours |

℃ |

≤0.5 |

Temperature variation with distance at between

10 mm and 50 mm above the die surface |

℃ |

≤1 |

| Temperature Resolution |

℃ |

0.1 |

| Interval of temperature recovering after changing testing samples |

minute |

≤4 |

| Timing range |

second |

0~6000 |

| Resolution of timing |

second |

0.1~1 |

| Inner diameter of die |

mm |

Φ2.095±0.005 |

| Inner diameter of filling canister |

mm |

Φ9.550±0.025 |

| Weights accuracy |

|

≤±0.5% |

| Standard weights |

g |

875,960,1200,1640 |

| Possible Combination of the Standard Weights |

g |

325, 1200, 2160, 3800, 5000 |

| Measurement range |

g/10min |

0.1~100 |

| Dimension |

mm |

550×430×730 |

| Power Supply |

|

220V±10%, AC, 50HZ, 3A |

| Weight |

kg |

65 |

| Cut-off device |

|

Automatic/Jog/Manual cut-off |

Standard Accessories

| Remark |

Quantity |

| Main machine (with built-in control panel, micro-printer, cylinder heater, cutting knife) |

1 set |

| Piston Rod (with a stud, a piston guide) |

1 set |

| Standard die of Φ2.095±0.005mm |

1 set |

| T-Shape Weights tray |

1 set |

| 5000g load Weights of 875g, 960g, 1200g, 1640g |

1 set for each |

| Die clean rod, cylinder Clean Rod, packing rod, filling funnel, feeder, wooden handle knife, cut-off blade for spare use |

1 set for each |

Test Load

| Load (g) |

Combination of dead weight (g) |

| 325 |

T-shape weight tray and the weight of piston |

| 1200 |

325+875 |

| 2160 |

325+875+960 |

| 3800 |

325+875+960+1640 |

| 5000 |

325+875+960+1640+1200 |

| 10000 |

325+875+960+1640+1200+2500+2500 |

| 21600 |

325+875+960+1640+1200+1600+2500+2500+2500+2500+2500+2500 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!