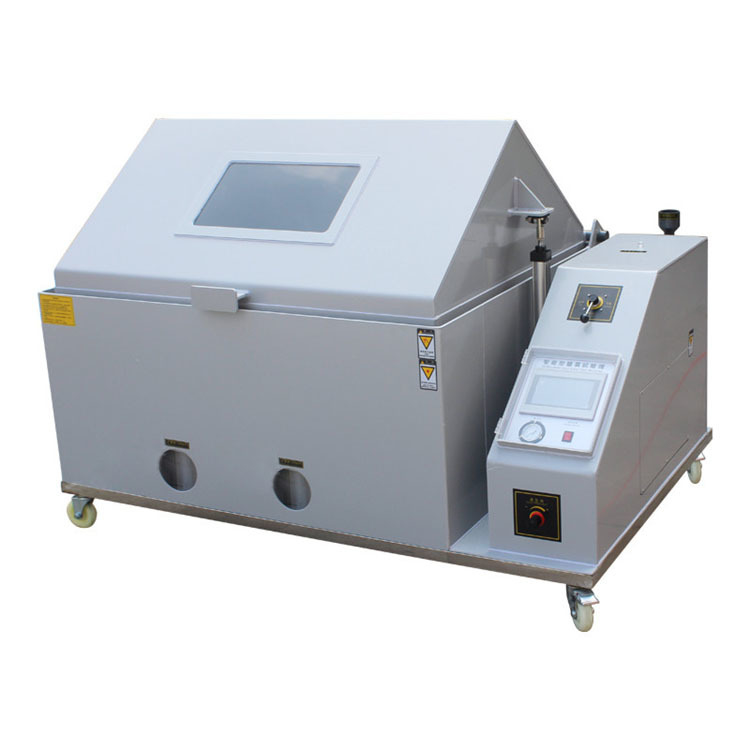

Environmental Test Chamber for Salt Spray Corrosion Testing Equipment X 60 for Zinc Plating Paint Coating

This Salt Spray Test Chamber is designed to meet the most widely recognized corrosion testing standards, including:

-

ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus

-

ISO 9227 – Corrosion Tests in Artificial Atmospheres (Salt Spray Tests)

-

ISO 7253 – Paints and Varnishes – Determination of Resistance to Neutral Salt Spray

-

ASTM G85 – Modified Salt Spray (Fog) Testing

These standards are essential for evaluating corrosion resistance in various materials and coatings.

Purpose & Applications

The Salt Spray Test Chamber is used to assess the durability and corrosion resistance of surface-treated materials, including:

Key Features & Benefits

Precision Testing – Simulates harsh salt-laden environments to predict real-world corrosion performance.

Wide Compatibility – Suitable for paints, electroplating, metal products, and coatings.

Standard Compliance – Meets ASTM, ISO, and other industry standards for reliable results.

Automated Control – Programmable test cycles for consistent and repeatable testing.

Durable Construction – Corrosion-resistant interior for long-lasting performance.

Corresponding standard of the Salt Water Spray Test Chamber for CASS, NSS Test:

1. GB/T 2423.17-1993 salt spray test

2. GB/T 2423.18-2000 salt spray test

3. GB/T 10125-1997 salt spray test

4. ASTM.B117-97 salt

5. JIS H8502 salt spray test

6. IEC68-2-11 salt spray test

7. IEC68-2-52 1996 salt spray test

8. GB.10587-89 salt spray test

9. CNS.4158 salt spray test

10. CNS.4159 CASS Accelerated acetic acid copper salt spray test

11. GB/T 12967.3-91 CASS Accelerated acetic acid copper salt spray test

Purpose :

Salt spray test machine is applicable for the salt spray corrosive test for the protection layer of components , parts , electronic and electrical parts and metal materials and industrial products

Chamber Structure:

1. Salt spray test machine cover is made of transparent materials so that the operator can see the tested sample in the chamber and the spraying situation of the tested sample .

2. A waterproof structure is adopted between the chamber cover and chamber body and thus there is no salt spray overflow .

3. Adopts the tower spraying system and equipped with the salt solution filter system and non-crystal nozzle so as to realize even salt spray distribution and freely adjustable settlement .

Main technical parameters :

| Model |

YY1015-60 |

YY1015-90 |

YY1015-120 |

| Inner box size: ( L×W×H ) cm |

60×40×45 |

90×60×50 |

120×100×50 |

| Outside box size: ( L×W×H ) cm |

107×60×118 |

141×88×128 |

190×130×140 |

| Equipment material: |

P.V.C & P.P |

| Temperature range: |

35°C~55°C |

| Temperature fluctuations: |

≤±0 . 5°C |

| Temperature uniformity: |

≤±2°C |

| Temperature precision: |

±1°C |

| Test chamber temperature: |

NSS ACSS 35±1°C CASS : 50±1°C |

| Saturated air barrel temperature: |

NSS ACSS 47±1°C CASS 63±1°C |

| Brine temperature: |

35°C±1°C |

| Spray quantity: |

1 . 0~2 . 0 ml / 80cm2 / hr |

| PH: |

NSS ACSS6 . 5~7 . 2 CASS 3 . 0~3 . 2 |

| Lab volume: |

108L |

270L |

600L |

| Brine tank capacity: |

15L |

25L |

40L |

| Power: |

1AC220V , 10A |

1AC220V , 15A |

AC 1 , 220V , 30A |

| Safety Devices: |

Overheating prevention circult-breaker,dehydration and

overheating prevention mechanism,breakdown indicator light |

| Standard accessories: |

Test salt, measure bucket, tool etc 1 set |

Specifications:

Salt Spray Test Chamber

1. Durable hard PVC construction

2. Anti-corrosion ,

3. Easy clean & operate

4. 1 year warranty

Features :

1. Low loading threshold for ergonomic loading and unloading..

2. "Easy Open' pneumatically operated canopy, with safety interlock.

3. Dry seal gasket to prevent wetting the operator's clothes.

4. Timed canopy lock and automatic purge of the cabinet interior with fresh air after testing and before the chamber is opened.

5. Easily accessible salt spray atomizer(s) in transparent hard-wearing acrylic, for ease of maintenance.

6. External portable salt solution tank for ease of cleaning. 115L for 300L, 73L for 450L, Chambers and 90L for 1000L Chambers and above.

7. Central viewing window for unimpeded visual access to chamber interior and test material.

8. Base castors and integrated fork lift lift truck runners, for ease of transportation.

9. A free choice of canopy colour.

10. Calibration certificate.

11. Consumables spares kit.

12. Fallout Measuring Kit.

People also ask:

1. What is salt spray test chamber?

2. Why choose a salt spray cabinet and Chambers?

3. What is a salt fog chamber?

4. What are the different types of salt spray test machine?

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!